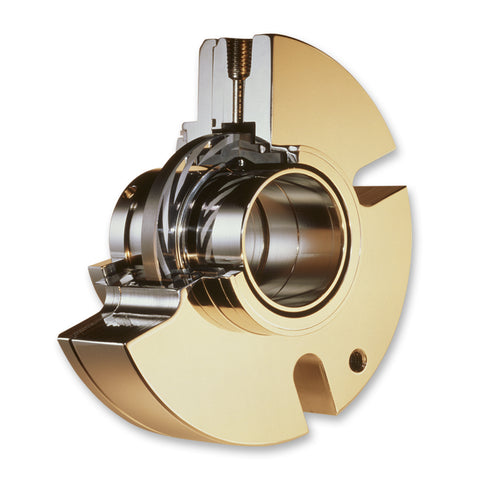

Type 2800EX

Patented John Crane spiral grooves are machined into the mating ring faces. A pressurized suitable inert gas is injected between the seals. As the shaft rotates, gas flows into the tip of the spiral groove and is compressed at the sealing dam, the ungrooved portion of the mating ring. At the sealing dam, gas is expanded. The resultant film pressure gives an opening force greater than the closing force, thus separating the faces. The Type 2800 spiral groove continues to operate, even if barrier gas pressure is momentarily lost, maintaining the gas film between the barrier gas and the process.